Meet the tech company growing diamonds in the desert. cnn

by Shawn Johnson March 7, 2024 in Innovation

Meet the tech company growing diamonds in the desert. cnn

Editor’s note: This series is, or was, sponsored by the country it highlights. CNN retains full editorial control over the content, reporting and frequency of articles and videos within the sponsorship, in compliance with our policy.

cnn-

Diamonds are the hardest substance on Earth – and comparatively difficult to find in nature.

For thousands of years, humans have dug deep into the earth in search of diamonds, creating some of the largest man-made pits in the world. Russia and South Africa which descend to 625 m (2,050 ft) Beneath the ground.

The intensive process has dangerous effects on both nature and humans Working conditions and practices Loss Ecosystem.

But mining is not the only way to obtain diamonds. According to the International Gem Society, the first laboratory-grown diamond (LGD) was produced in the 1950s. And the technology continues to advance, enabling laboratories to grow gem-quality crystals at affordable prices – up to 80% cheaper – without the sustainability and ethical concerns of mining.

And growing diamonds artificially means you can bring diamonds Production in the most unexpected places – including the desert.

The United Arab Emirates (UAE) is the global leader in diamond imports and exports, but it has no diamond mines. So entrepreneur Mohammed Sabeg saw an opportunity to not only trade diamonds, but also develop them.

In 2022, he co-founded the Dubai-based company 2DOT4 Diamonds has become the first to produce, cut and polish lab-grown diamonds in the UAE.

“Our idea was to bring the mine to the consumer,” says Sabeg. “Instead of shipping diamonds around the world, diamonds are produced and sold locally.”

The company’s name, 2DOT4, comes from the refractive index of diamond – the speed at which light passes through diamond compared to air, which is about 2.4 times slower.

For Sabeg, having a name related to a physical property of a gem indicates that pieces produced in the laboratory are similar to those in nature.

“The only difference is that we control the pressure, we control the heat, we control the gases,” he says. “Mined diamond, you don’t control it, the earth is doing it.”

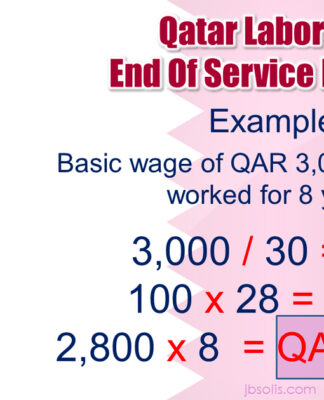

Sabeg explains that to grow a diamond, you start with a diamond, whether it’s lab grown or mined. This is called the “seed” and is usually about 0.3 to 0.6 millimeters thick. (2DOT4 makes its own seeds from home-grown diamonds.)

When placed inside a reactor, the seeds are exposed to gases such as hydrogen, methane, oxygen and argon. It also undergoes pressures of up to 180 tors – about two-thirds the pressure at the peak of Mount Everest – and reaches temperatures of 1,000 °C (1,832 °F). In this way, carbon is gradually deposited onto thin slices.

Then, it’s time to increase the volume.

“You set the speed of development using different parameters: the lower your speed, the better your quality,” Sabeg explains.

On average, 2DOT4 grows its diamonds at a speed of about 0.01 millimeters per hour. This means that every 24 hours, the stone increases in length by an amount equal to the thickness of two sheets of paper.

Once the diamond height is at least five millimeters, the piece is called a “block”, and has three possible outcomes. It can be cut into more seeds, which will be put back into the reactors to grow more diamonds. Or, depending on demand, 2DOT4 will cut and polish the gemstone. This can then either be sold to jewelers and designers, or turned into a piece of jewelery designed in-house.

Currently, the US, China and India dominate LGD production, with the latter two accounting for more than two-thirds of global production, according to diamond industry’s Paul Zimnisky. Analyst and consultant based in the US.

Apart from jewellery, lab-grown diamonds are used in many industries, especially when it comes to making tools that cut dense materials like concrete, marble and metals.

For example, China “has a multi-decade legacy of producing synthetic diamonds for abrasive industrial application, so they also have the know-how and infrastructure to become a major producer of man-made diamonds for jewellery,” Zimnisky explains.

India, on the other hand, has long been a leader in diamond cutting and polishing, and has also adopted LGD technology to jump-start production. Last year, the country introduced tax reforms in the sector and pledged additional funding to further expand its man-made diamond industry.

Ahmed bin Sulayem, CEO and executive chairman of the Dubai Multi Commodities Centre, says that given the UAE’s position as a top diamond trading hub and its diversification efforts away from oil, expanding into the lab-grown diamond industry is a key to its economy. Could be an important step. (DMCC), a global trade center that organized the first Lab-Grown Diamond Symposium.

“With the rise of the LGD industry symbolizing the intersection of technology and business, its potential is huge, [and] “We are excited to see Dubai established as a leading force in this transformative era,” says Bin Sulayem.

“Sixty years ago, if you told someone it was a synthetic or lab-grown diamond, they wouldn’t even look at it,” he adds. But younger generations are more concerned about the ethical and environmental issues associated with mining, and are attracted to the affordability of luxury goods, “so the industry has to adapt,” he says.

However, entering the LGD production sector can be a challenge. According to Zimnisky, it will be difficult to compete with India and China on a large scale, “unless you have a competitive advantage, or you have a niche or a specialized business.”

other united arab emirates Companies are following 2DOT4 and setting up their LGD business in Dubai Ivike Diamonds, part of the HRA Group, established its production facility in the emirate just a few months ago. During this, Local brands like Attica and Ioni are marketing their designs using only lab-grown gemstones.

For DMCC, the goal is to encourage all production to be done in-house, as a way to add value to the final product and strengthen local industry.

“The main message we are giving to the lab-grown diamond industry is not to waste your time selling diamonds: focus on the final art,” says Bin Sulayem.

For Sabeg, the hope is that 2DOT4’s creations are laying the foundation for the future of LGD production in a country that currently imports more diamonds than anywhere else in the world.

“Our way of looking at what we’re doing is setting a standard in the industry,” he says.

Source: www.cnn.com